Reasons for detecting glass stress

The glass stress meter is named after the application of polarized light interference principle to check the internal stress of glass, Which is specially used to detect the internal stress of glass bottles. It can be used for ampoules, vials, infusion bottles, wine bottles, cans, cosmetic bottles and other glass containers, and to control the quality of glass bottles.

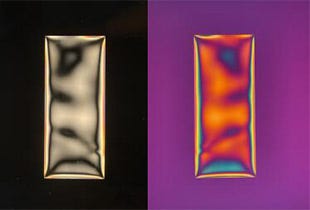

The stress of the glass directly affects the strength of the glass. The thermal breakage of glass is caused by excessive thermal stress, the impact rupture of glass is caused by the excessive mechanical stress generated by the mechanical impact or impact force of the glass. And the self-explosion of glass is caused by excessive internal stress of the glass. In addition, the increase in the strength of the glass due to thermal or chemical tempering is due to the increase in the surface compressive stress of the glass. Therefore, the stress and strength of glass are inextricably related. Most of the stresses that can be detected by the stress meter is thermal stress. Thermal stress is caused by temperature gradients, this is because glass is an amorphous product that is melted at high temperature and solidified by rapid cooling. Therefore, during the production process, the temperature changes of various parts of the glass plate surface cannot be uniform, so thermal stress will be generated. Because of this, glass bottles need to go through the annealing process, but there will still be residue. With the help of the glass stress meter of Suzhou PTC Optical Instrument Co., Ltd., it is possible to determine whether the residual stress of the glass bottle meets the relevant standards.

https://www.ptc-stress.com/reasons-for-detecting-glass-stress/